co2 laser skin resurfacing machine Safety Features You Need to Know

2025-12-24 09:12:11

When investing in aesthetic technology for your clinic, safety concerns often keep practitioners awake at night. Will equipment malfunction during a procedure? Could thermal damage cause complications? These aren't just hypothetical worries—they're real concerns that demand serious attention. Understanding the essential safety features of a co2 laser skin resurfacing machine protects both your patients and your practice, ensuring that cutting-edge skin rejuvenation treatments deliver stunning results without compromising wellbeing. With laser technology advancing rapidly, knowing which safety mechanisms truly matter separates professional-grade equipment from inadequate alternatives.

Understanding Critical Safety Mechanisms in CO2 Laser Technology

Modern co2 laser skin resurfacing machine systems incorporate multiple layers of protection designed to prevent operator errors and equipment failures. The foundation begins with precise laser wavelength control at 10.6μm, which ensures optimal water absorption in skin tissue while minimizing unintended thermal spread. Professional systems utilize metal tube solid-state lasers that maintain consistent energy output throughout treatments, preventing dangerous power fluctuations that could cause burns or inconsistent results. Advanced cooling systems represent another non-negotiable safety feature, as they actively prevent overheating of both the machine components and treated skin surfaces. Water cooling mechanisms continuously circulate refrigerated fluid to dissipate heat generated during high-intensity procedures, maintaining safe operating temperatures even during extended treatment sessions.

Advanced Cooling Systems for Thermal Protection

The cooling system in a co2 laser skin resurfacing machine directly impacts patient safety during fractional resurfacing treatments. Unlike air-cooled alternatives that struggle during demanding procedures, water cooling systems provide consistent thermal management across all power levels from one watt to over forty watts. This becomes particularly crucial when treating sensitive facial areas or performing multiple passes on scarred tissue. The cooling mechanism works in tandem with the laser's pulse control, allowing practitioners to deliver therapeutic energy while preventing the accumulation of residual heat that causes complications. Professional-grade equipment monitors coolant temperature continuously, triggering automatic shutdowns if thermal thresholds are exceeded, which protects patients from thermal injuries and preserves the longevity of expensive laser components.

Precision Energy Control and Real-Time Monitoring

Safety in laser treatments depends heavily on precise energy delivery, which is why advanced co2 laser skin resurfacing machine models feature sophisticated power regulation systems. These systems allow adjustable output from one to forty watts with actual output exceeding nominal specifications, giving practitioners the flexibility to customize treatments while maintaining safety margins. The integration of indicating light systems using 635nm wavelength provides visual confirmation of treatment areas before applying therapeutic laser energy, preventing accidental exposure to surrounding tissues. Touch screen interfaces with intuitive controls enable practitioners to make real-time adjustments during procedures, responding immediately to patient comfort levels and tissue responses. Energy self-inspection technology continuously monitors output consistency, automatically compensating when laser tube efficiency decreases over time, which ensures predictable results throughout the equipment's operational lifespan.

Operator Safety Features and Protection Protocols

Beyond patient protection, comprehensive safety features for co2 laser skin resurfacing machine operation must safeguard the clinical team performing treatments. Professional systems incorporate multiple interlock mechanisms that prevent laser activation unless all safety protocols are satisfied, including proper handpiece connection, adequate coolant levels, and closed treatment room conditions. The seven-joint articulated light guide arm systems found in quality equipment minimize operator exposure to reflected laser energy while providing excellent maneuverability during facial contouring treatments. Remote interlock warning alarms alert staff immediately when safety parameters are compromised, such as coolant depletion or electrical irregularities. These audible and visual alerts ensure that no treatment proceeds under unsafe conditions, protecting both patients and practitioners from preventable incidents.

Eye Protection and Optical Safety Standards

Laser eye safety represents one of the most critical aspects of co2 laser skin resurfacing machine operation, as the 10.6μm wavelength can cause permanent corneal damage with even brief exposure. Professional treatment protocols mandate proper eye protection for both patients and all personnel present during procedures. Patients require specialized corneal shields or occlusive eye protection that blocks laser wavelengths while maintaining comfort during facial treatments. Clinical staff must wear wavelength-specific safety eyewear that filters CO2 laser emissions without compromising visibility of the treatment field. The indicating light system serves double duty here, allowing practitioners to visualize treatment patterns without activating the therapeutic laser, which reduces overall eye exposure during setup and adjustment phases.

Fire Prevention and Flammability Management

The high energy density of co2 laser skin resurfacing machine systems creates fire risks that demand specific safety protocols during operation. Research has demonstrated that dry materials including towels, gauze, and endotracheal tubes can ignite when exposed to multiple laser passes, while moistened materials resist ignition effectively. Professional practices maintain strict protocols requiring all draping materials, applicators, and materials near the treatment field to remain thoroughly moistened throughout procedures. Ophthalmic ointments and petroleum-based products must be applied sparingly and kept away from direct laser exposure, as these materials can vaporize and combust under sustained laser energy. Treatment rooms should contain appropriate fire suppression equipment including carbon dioxide or dry chemical extinguishers rated for electrical fires, ensuring rapid response capability should combustion occur despite preventive measures.

Certification Standards and Regulatory Compliance

Investing in a co2 laser skin resurfacing machine requires verification that equipment meets international safety and quality standards through recognized certification programs. CE certification demonstrates compliance with European Union medical device regulations covering electrical safety, electromagnetic compatibility, and clinical efficacy. ISO 13485 certification verifies that manufacturers maintain quality management systems specific to medical device production, ensuring consistent manufacturing standards and traceability. These certifications aren't merely bureaucratic formalities—they represent independent verification that equipment design, component selection, and manufacturing processes meet rigorous safety benchmarks established through decades of clinical experience and engineering analysis.

Understanding Medical Device Quality Management

The ISO 13485 standard specifically addresses medical device quality management systems, requiring manufacturers to document and control every aspect of production from component sourcing through final testing. For co2 laser skin resurfacing machine buyers, this certification provides confidence that equipment undergoes systematic quality inspections before shipment. Certified manufacturers maintain detailed records of laser tube performance, optical component specifications, and electronic system testing, which supports troubleshooting and warranty service throughout equipment lifespan. The standard mandates risk management processes that identify potential failure modes during design phases, leading to redundant safety systems and fail-safe mechanisms that prevent dangerous malfunctions. Practitioners purchasing certified equipment gain access to comprehensive technical documentation, training materials, and clinical support resources that enhance safe operation.

FDA Approval and Clinical Safety Validation

While CE and ISO certifications demonstrate manufacturing quality and European regulatory compliance, FDA approval provides additional validation of clinical safety and efficacy through rigorous American regulatory standards. Manufacturers pursuing FDA certification for co2 laser skin resurfacing machine equipment submit extensive clinical data demonstrating safety profiles across diverse patient populations and treatment protocols. The approval process examines adverse event reporting, long-term outcomes, and comparison data against existing treatment modalities. Equipment with pending FDA approval indicates manufacturer commitment to meeting the highest international standards, though practitioners should verify current approval status before purchasing. FDA-cleared devices undergo post-market surveillance requiring manufacturers to report complications and implement corrective actions when safety concerns emerge, providing ongoing protection for practitioners and patients.

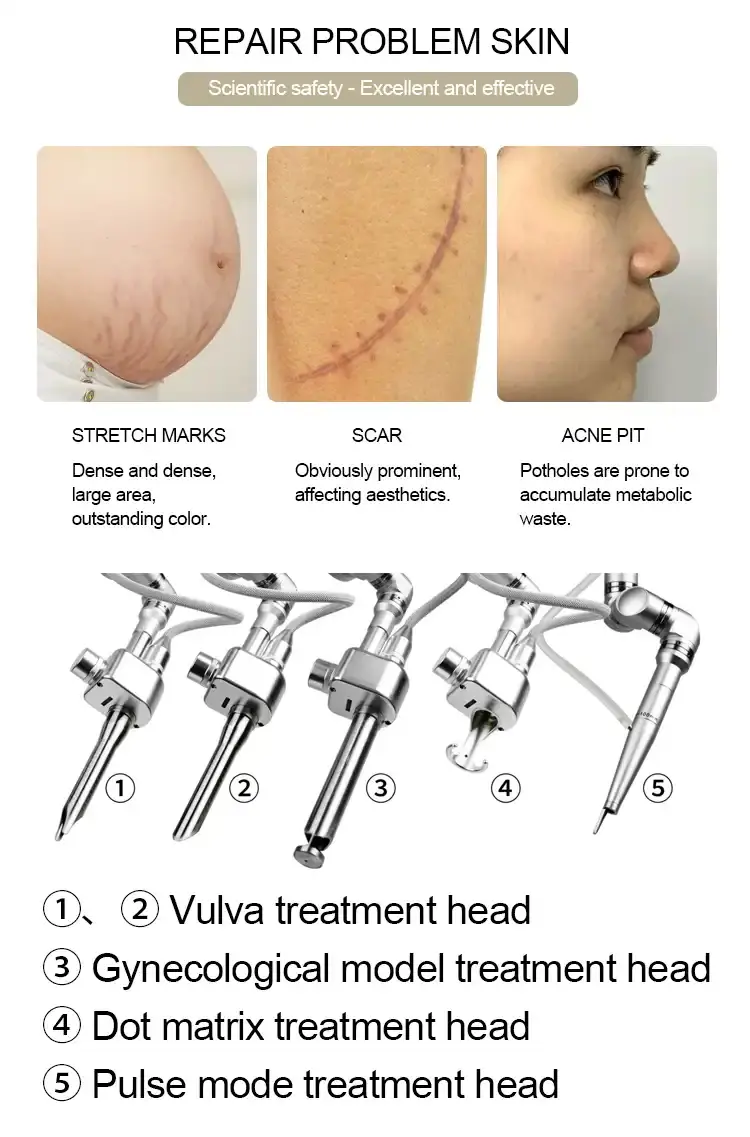

Treatment Mode Versatility and Safety Implications

Modern co2 laser skin resurfacing machine systems offer multiple output modes including dot matrix, pulse, ultra pulse, and specialized vaginal tightening settings, each carrying distinct safety considerations. Dot matrix mode delivers fractionated laser energy in precisely spaced microbeams, leaving surrounding tissue intact to accelerate healing while reducing complication risks compared to full-surface ablation. Pulse mode provides controlled energy bursts suitable for graduated treatments where practitioners build intensity progressively based on tissue response. Ultra pulse mode generates maximum peak power with minimal pulse duration, enabling deep penetration with reduced residual thermal damage for effective ablation with minimal inflammation. Each mode requires specific training and understanding of tissue interaction physics to prevent overtreatment or inadequate energy delivery.

Customizable Treatment Parameters for Patient Safety

The ability to adjust spot size, scan shape, and treatment density on a co2 laser skin resurfacing machine allows practitioners to customize procedures matching individual patient anatomy, skin type, and treatment objectives. Equipment offering scan shapes including ellipse, rectangular, triangle, hexagon, round, and custom graphics enables precise treatment of irregular anatomical features like perioral rhytids or acne scarring patterns. Adjustable spot size starting at 0.1mm focus diameter provides the precision necessary for delicate periorbital treatments while minimizing thermal spread to surrounding tissues. These customization capabilities enhance safety by allowing conservative initial treatments that can be intensified in subsequent sessions based on patient healing responses, rather than aggressive single-treatment approaches carrying higher complication risks.

Conclusion

Comprehensive safety features in co2 laser skin resurfacing machine equipment protect patients, practitioners, and practice reputations through multi-layered protection systems. From advanced cooling mechanisms and precision energy control to regulatory certifications and customizable treatment parameters, these safety elements distinguish professional medical devices from inadequate alternatives. Prioritizing equipment with robust safety credentials ensures predictable outcomes and minimizes liability exposure.

Cooperate With Xi'an Taibo Laser Beauty Company

As a China co2 laser skin resurfacing machine manufacturer with over fifteen years of production experience, Xi'an Taibo Laser Beauty Company delivers professional equipment trusted across 180 countries worldwide. Our comprehensive product line includes fractional co2 laser systems certified to CE and ISO 13485 standards with pending FDA approval. As a leading China co2 laser skin resurfacing machine supplier, we provide complete OEM and ODM customization services tailored to your branding requirements. Our China co2 laser skin resurfacing machine factory maintains dedicated production departments, quality inspection systems, and R&D teams ensuring consistent excellence. Whether you're seeking High Quality co2 laser skin resurfacing machine for sale or competitive co2 laser skin resurfacing machine price quotations, our experienced sales team provides comprehensive support. We offer two-year warranties, professional training, 24-hour technical assistance, and flexible shipping via air, sea, rail, or express courier. For China co2 laser skin resurfacing machine wholesale opportunities or exclusive distribution partnerships, contact susan@taibobeauty.com today. Visit our exhibitions globally, experience our advanced technology firsthand, and discover why practitioners worldwide trust Taibo for their aesthetic equipment needs.

References

1. Rohrich RJ, Janis JE, Pownell PH. "CO2 Laser Safety Considerations in Facial Skin Resurfacing." Plastic and Reconstructive Surgery, 1997.

2. Alster TS, West TB. "Safety and Efficacy of High Fluence CO2 Laser Skin Resurfacing with a Single Pass." Dermatologic Surgery, 2001.

3. Goldman MP, Fitzpatrick RE. "Laser Carbon Dioxide Resurfacing." National Center for Biotechnology Information StatPearls, 2023.

4. Anderson RR, Parrish JA. "Fractional Laser Technology and Clinical Applications in Dermatology." Journal of the American Academy of Dermatology, 2004.

5. Ross EV, McKinlay JR, Anderson RR. "Thermal Injury Profiles and Safety Parameters for Carbon Dioxide Laser Resurfacing Systems." Lasers in Surgery and Medicine, 1999.

YOU MAY LIKE